Plastics

Plastics must have completely different characteristics depending on the application so that they can be used reliably

All-inclusive

From us$198

Book Now

During plastics analytics and inspection, we analyses plastics to characterize their thermal characteristics and decomposition behavior. We determine the water content of your sample, identify and quantify decomposition products released, as well as the material composition.

BQIS Plastics Inspection

• Visual inspection: Check for defects such as bumps, cracks, and chipping.

• Crocking check: Rub the product with a wet white cloth to check for pigment transfer.

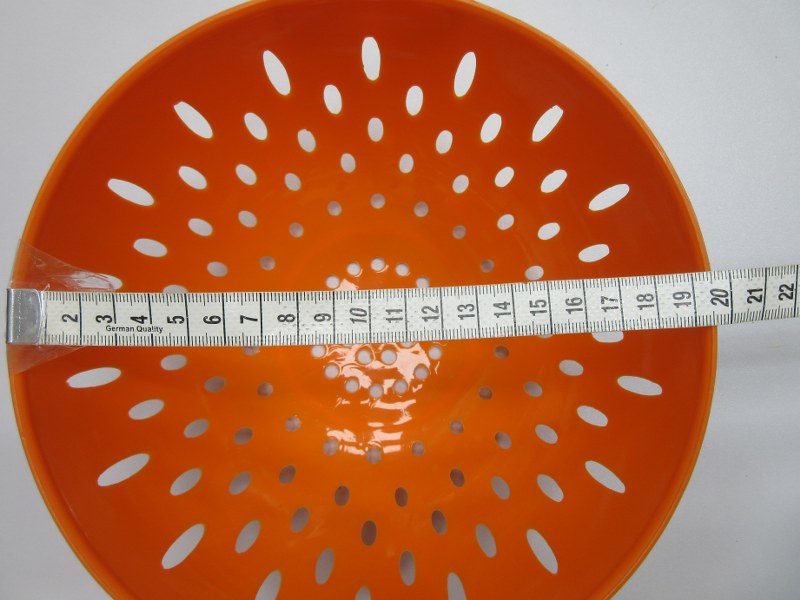

• Opacity evaluation: Use an opacity meter to measure the product’s opacity.

• Transparency evaluation: Use a tester to determine the product’s transparency rating.

• Material testing: Confirm that the plastic has the desired properties, such as strength, flexibility, and durability. Material testing techniques include tensile testing, impact testing, and thermal analysis.

• X-ray inspection: Use X-ray inspection systems to inspect plastics

Other types of plastics inspection include

• Checking for resin defects, surging, poor mixing, fractures, overheating, moisture release, trapped air, and contamination

• Checking for cracks, pits, chips, warping, shrinkage, stress, and other deformities

Let’s Chat

Donec sollicitudin molestie malesuada. Praesent sapien massa, convallis a pellentesque nec, egestas non nisi. Praesent sapien massa, convallis a pellentesque nec.